Laser cutter

The plush toy laser cutting machine is specially designed for the processing of plush fabrics and batches of various kinds of garment fabrics, vacuum suction and crawler transfer worktables, which make the feeding and conveying convenient and fast.

Features:

1. Select Taiwan’s silver linear motion guide rail to ensure smooth, high speed and no vibration of the laser head during operation. With the characteristics of the small slit, high speed and high precision, the accuracy and service life of the equipment are guaranteed.

2. Software automatic layout function. After the cutting pattern is designed, the software automatically formats and the materials are closely matched to reduce waste.

3, Singapore imported metal molybdenum reflective lens and gallium arsenide focusing lens, resistant to sputum, high temperature, no need to change frequently, reduce the cost of use, fine spots, uniform light.

4. Advanced shifting system, which realizes the function of instantaneous shifting and self-adjusting speed according to the needs of curved and straight lines during the cutting process, so that the cutting edge is smooth and the corner curve is natural.

5. Fully enclosed water tank to ensure that the water in the circulation and laser tube is dusty and clean, prolong the service life of the laser tube, and effectively reduce the production cost.

JQ1810 toy fabric two-head interactive laser cutting machine selects the crawler type working platform, the double laser head mutual processing, and the automatic discharging system combine, the cutting speed is fast, the fabric utilization rate is high, and the automatic feeding system can be equipped to realize continuous feeding cutting. It is especially suitable for the cutting of materials such as plush materials and composite fabrics. 100W glass tube sealed off CO2 laser, 1800mm × 1000mm crawler type working platform, accuracy ±0.01mm, can be equipped with automatic feeding.

Cotton filling machine:

The filling machine, also known as the filling machine, is a machine that fills the filling of PP cotton into a plush toy, a sofa pillow cushion, a pillow or a pillow shell. Generally suitable for industries such as plush toys, home textiles, furniture, and clothing.

The cotton filling machine generally adopts a cold plate as the casing, the surface is sprayed or painted, the inside has a stirring device, the bottom is equipped with a small gas storage tank, and the front has a foot switch device. First use PP or other equipment to suck PP cotton, pearl cotton, plastic particles, foam material or other filler into the cotton filling machine. The filling will be fully stirred in the cotton filling machine, stepping on the foot switch, using gas. The impulse fills the filling into the desired product shell to complete the filling process.

The cotton filling machine has two advantages over manual filling:

1. High work efficiency. A double-headed cotton filling machine can handle the workload of ten to fifteen people, and the use of a cotton filling machine can greatly reduce labor costs.

2. The quality of the products being filled is good. The product filled with the cotton filling machine is full and even and is much better than the hand-filled hand.

According to the discharge port, the cotton filling machine can be divided into a single head and a double head. According to the foot switch, it can be divided into a mechanical valve filling machine and an electronic valve filling machine.

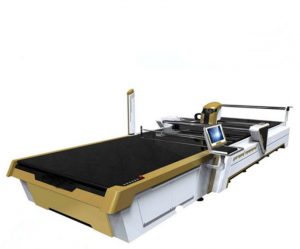

Automatic cutting machine

The automatic cutting machine is an automatic cutting device used in the textile and garment, leather industry, car seat and furniture industries.

Structure:

Chain bristles cutting table; double X-axis, Y-axis gear width drive, brushless servo motor drive system; robust head and cutter head design; modular 4-disc whetstone automatic sharpening system; high efficiency vacuum generation It is equipped with silencer, dust, and debris filter system; the head configuration mode LCD screen, manual crank handle, easy to operate.